Versatile world of LED strips, Aluminium Profiles and lighting controls provides endless possibilities in creations of unique, artistic yet user-friendly installations. LED strips, aluminium profiles and lighting controls became

designers’ must-haves in every project, it could be small domestic or large commercial installations. Planning for projects involving LED strips, Aluminium profiles and Lighting controls very often been neglected and can cause problems at finishing stage. In most cases discussion of LED strips and controls been left to the end of project and that can lead to limited solutions or decision not to use LED strips at all.

"LED strips,

aluminium profiles and lighting controls

became designers’ must-haves

in every project"

To Avoid any disappointment generally there is couple points that need to be addressed at the beginning stage of the project:

- Clear Vison of end-result – Designers and End customer must have clear view what they like to achieve, this will direct supplier (us) in correct path of choosing right materials and we also can discuss preferred way of installations with installer (electrician)

- Choosing of appropriate materials and installation methods – this needs to be discussed between installer and supplier at the first fix stage as it will determine cabling, location of controls and type of aluminium profile.

Example of procedural aproach during recently completed project

1) The interview :

Lumeno engineer meets up with the decision making manager of the hotel along with probably the most important member of the party the installer/electrician – during our meeting we got all required information to provide with best possible offer.

Hotel Manager and installer describe requirements/expectations:

- Lighting controls upgrades – centralized single control with pre-programed scenes and possibility of changing scenes if required by management.

- Integration of existing lighting that doesn’t need upgrade into a new centralized lighting control.

- Upgrade of Ceiling coving LED strips to achieve Full colour changing and, in most cases, (60% of time) to have Extra Warm White colour (2200K).

- Wiring preferences and posibilities discussed with the electrician – in this case electrician preferred centralized location of the gear.

2) Solution finding :

At this stage we choose most appropriate products to achieve required results - DALI based system would be the most appropriate for the project, as It accommodates all requirements. As soon as we decided on the gear, we submitted full quotation for approval allong with proposed wiring schematics to the installer.

3) Build & Supply :

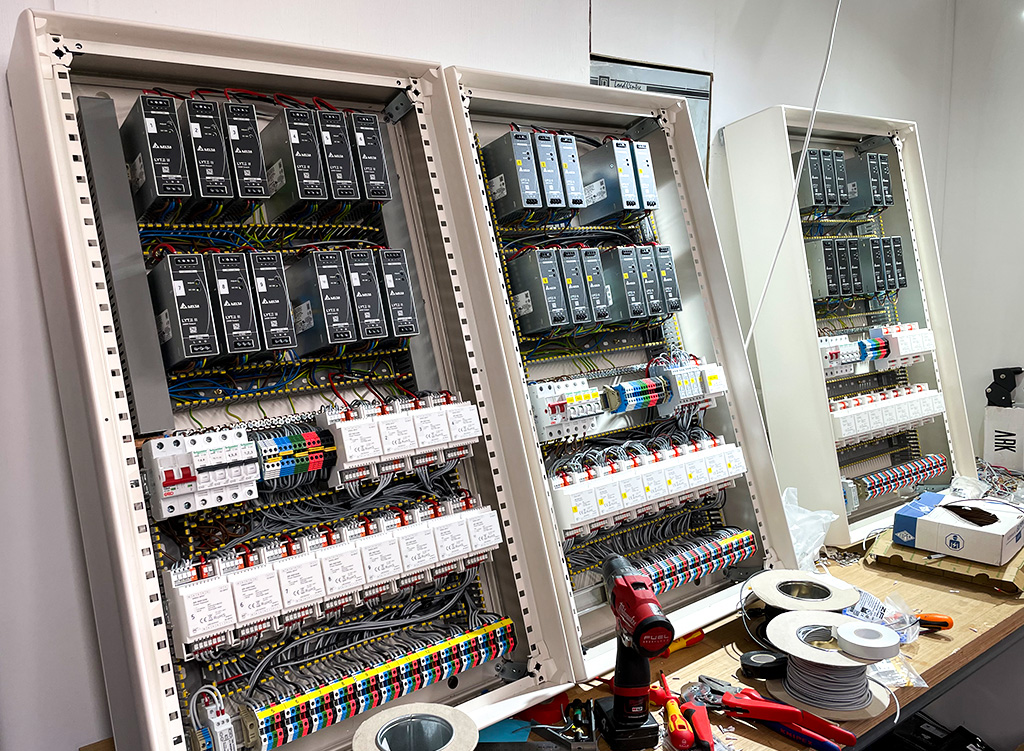

After finalizing with the installer all extra wiring requirements, 4 control panels were supplied specifically design for this projects, encapsulating all DALI control devices and power supplies. Easy connection terminals were provided with detailed described terminals for the installer to run cables from strips and other light fittings involved directly to the boards. Control gear grouped into boards as per below images, was than positioned in 4 different locations and interlinked with DAIL bus cable. Pre-making of the boards makes installations much faster and simpler, and easier on maintenance.

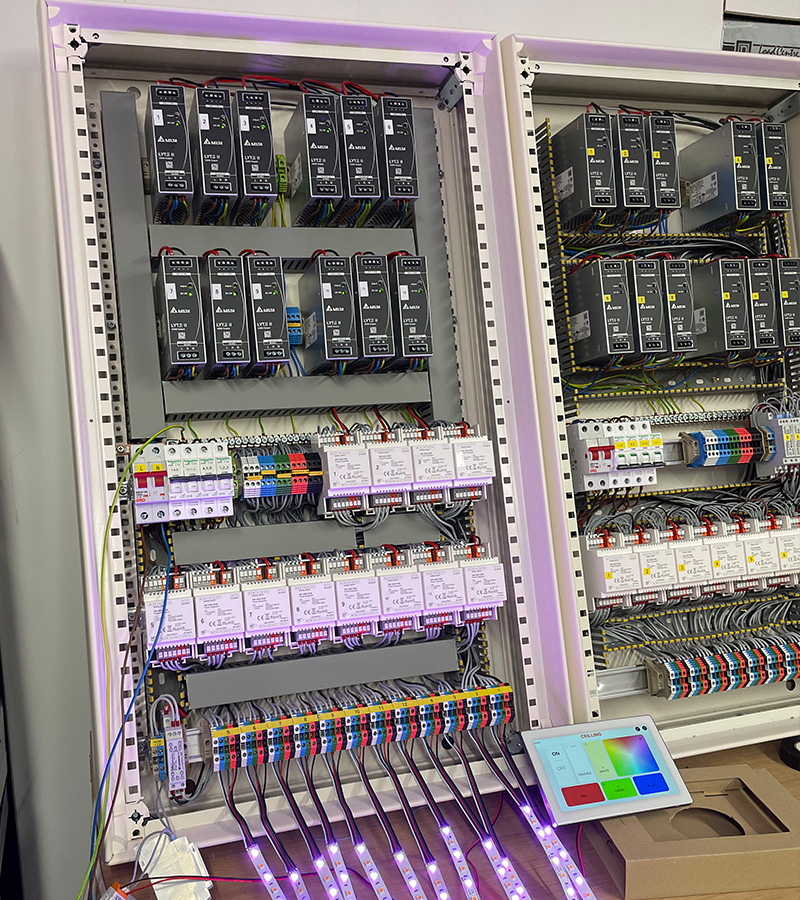

testing RGB controlls

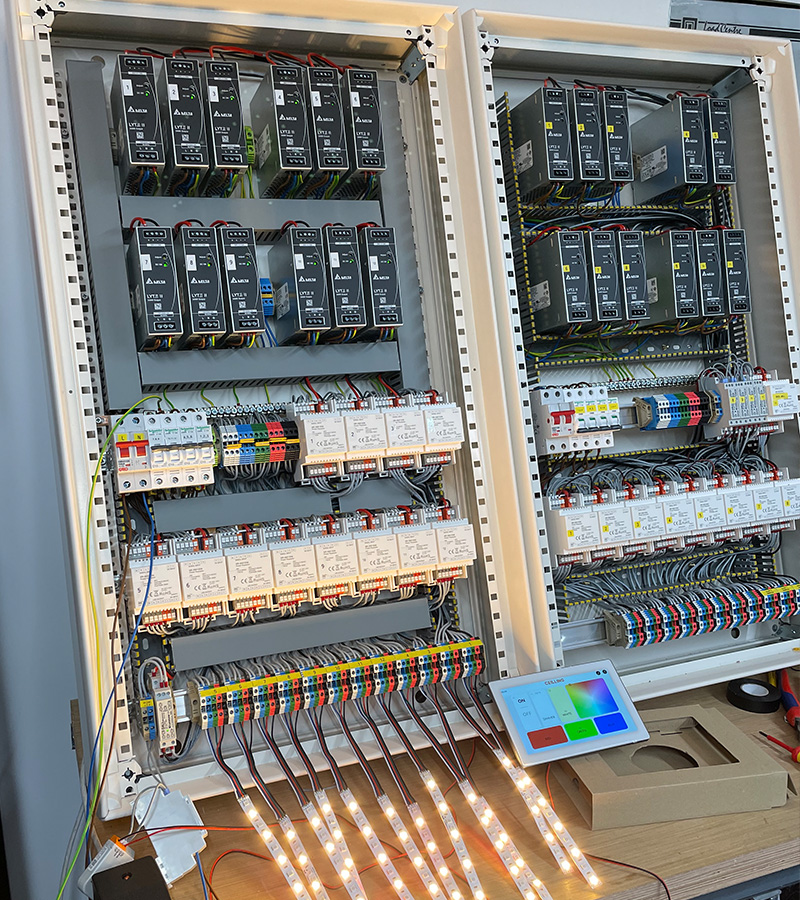

testing RGB controlls testing white dimming range

testing white dimming range"With a proper planning,

it is possible to achieve

all off clients requirements and

make installation process

go smooth."

4) Results & commisioning

DALI system supplied allows integration of existing lighting via various cross-platform interfaces. In case of this hotel it was 0-10V dimmable lights controlled via DALI => 0-10V bridge. All lights had been programmed and operated via 7inch touch screen. Touch screen afterwards was password protected to avoid accidental or potentialy malicious change of settings.

As ceiling lights, clients chose RGB-XW strip where XW stands for 2200K, backed-up with basic aluminium profile serving a role of a heat dissipation surface.

extra warm setting - full on

extra warm setting - full on function room zoning - split controls

function room zoning - split controls Even colours - St. Patric's : Green

Even colours - St. Patric's : Green Event colours - New Year's Night : Purple

Event colours - New Year's Night : PurpleAt commissioning stage, our engineer duo, went through final adjustments with the clients to fine tune settings, set lighting scenes and pre-sets and customize interface functionality to their specific needs.

All pieces formed a perfect working system with client coming back for more solutions in the months following the installations.

Conclusion:

With a proper planning ahead, it is possible to achieve all off clients requirements and make sure the installation process go smooth.